Oxygen-enriched Pulverized Coal Injection in Blast Furnaces

Date: 2025-9-22

Category: Metallurgical encyclopedia terms

Views: 172

Oxygen-enriched pulverized coal injection in blast furnaces is a core technology that involves simultaneously injecting pulverized coal and oxygen-enriched air into the blast furnace to replace part of the coke and optimize the smelting process.

The process and technology revolve around "efficient coal injection, stable operation, and energy conservation".

I. Core Process Flow

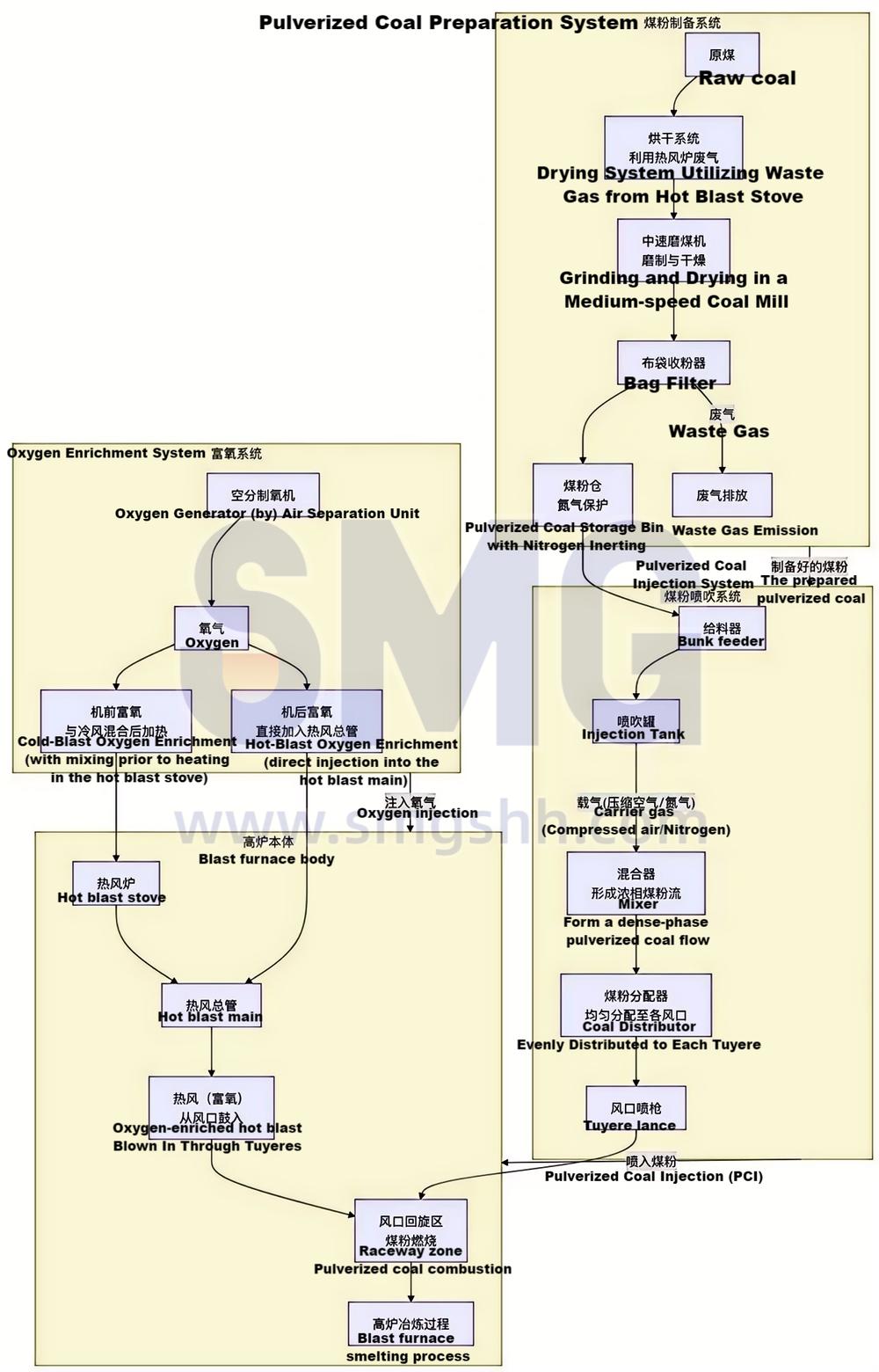

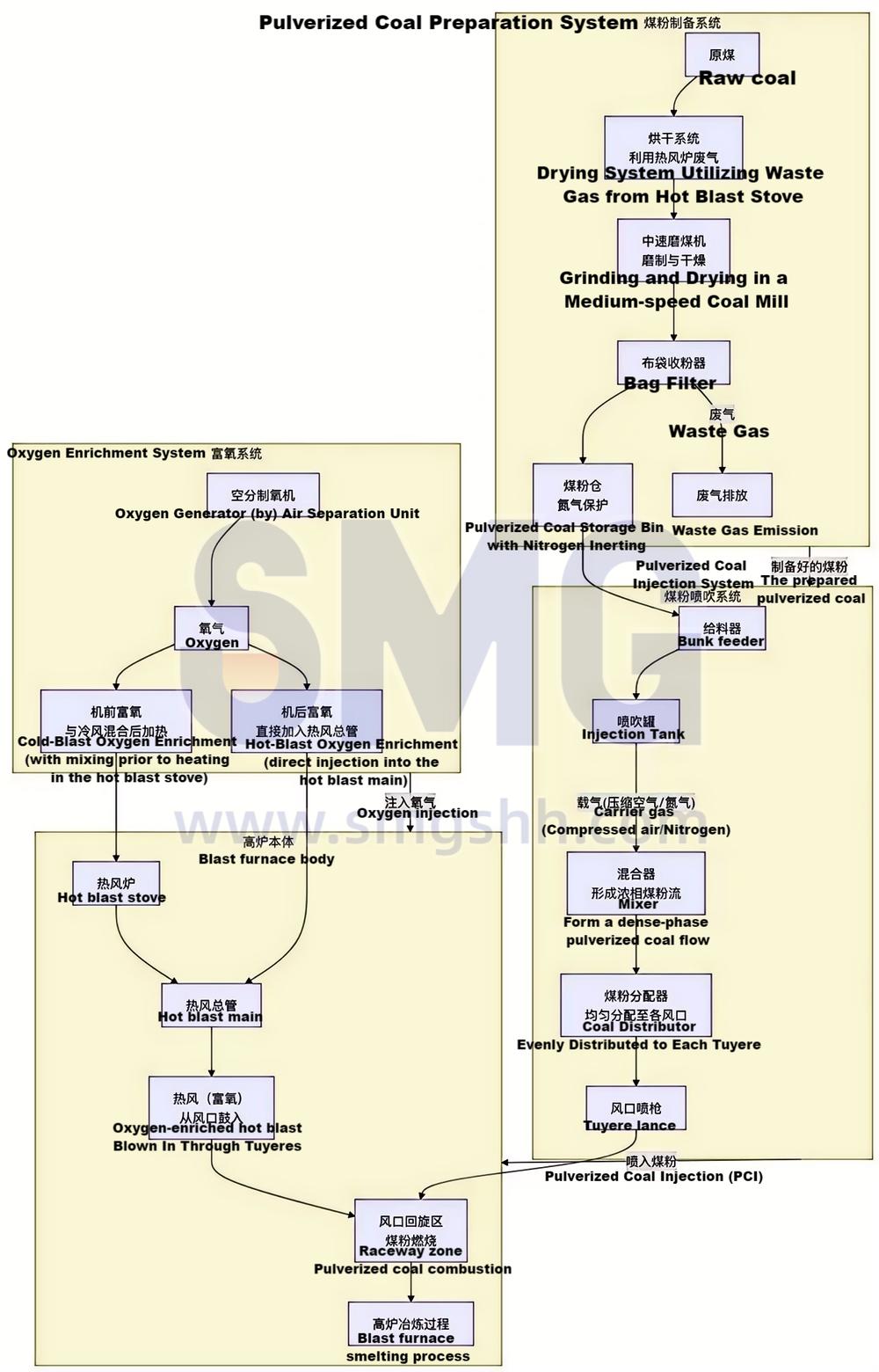

1. Pulverized coal preparation and transportation: Use medium-speed coal mills to grind raw coal into fine coal powder with a particle size of ≤0.074mm accounting for 70%-80%, dry it with hot air (control moisture content ≤1%), and then transport it to the blast furnace injection system through nitrogen or inert gas to prevent spontaneous combustion and explosion of the coal powder.

2. Preparation and supply of oxygen-enriched air: Produce oxygen-enriched air with an oxygen concentration of 21%-30% through oxygen generators (such as pressure swing adsorption or cryogenic methods), heat it to over 1000℃ in a hot blast stove, and then mix it with cold air and send it into the blast furnace through the tuyeres.

3. Pulverized coal injection: The pulverized coal is mixed with oxygen-enriched air through the injection lance (inserted into the tuyere) and burns rapidly in the tuyere area, releasing heat and generating reducing gases such as CO and H2, which participate in the reduction of iron oxides.

4. Regulation of furnace conditions: After coal injection, adjust the air volume, oxygen enrichment rate, and coal ratio (pulverized coal injection per ton of iron) in real time to maintain a stable hearth temperature (to avoid a decrease in furnace temperature due to excessive coal injection) and ensure smooth material descent (reduce hanging and collapsing of materials).

II. Key Technical Points

1. Pulverized coal quality control technology: Select bituminous coal or a mixture of bituminous and anthracite coal with ash content ≤10%, volatile matter 20%-30%, and sulfur content ≤0.8% to reduce the impact of harmful elements on the quality of molten iron and ensure the combustion efficiency of the pulverized coal in the tuyere.

2. Matching technology of oxygen enrichment rate and coal ratio: For every 1% increase in the oxygen enrichment rate, the pulverized coal injection can be increased by 15-20kg/t iron; typically, control the oxygen enrichment rate at 23%-27% and the pulverized coal injection at 180-250kg/t iron to avoid incomplete combustion of the pulverized coal due to insufficient oxygen enrichment (increasing the carbon content in the slag) or damage to the tuyere due to excessive oxygen enrichment.

3. Optimization design technology of injection lance: Use double-tube or multi-hole injection lances to ensure thorough mixing of the pulverized coal and oxygen-enriched air, extend the residence time of the pulverized coal in the tuyere swirling zone, and increase the combustion rate (target ≥95%).

4. Intelligent monitoring and control technology: Through real-time analysis of blast furnace gas composition (monitoring CO, CO2, and H2 content), hearth temperature detection (infrared or thermocouple), and material surface position monitoring (radar), combined with AI models to dynamically adjust the pulverized coal injection and oxygen enrichment rate, achieving stable smelting.

III. Technical Advantages and Application Value

1. Cost reduction and efficiency improvement: Each ton of pulverized coal can replace 0.8-0.9 tons of coke, and coke costs account for more than 50% of the blast furnace ironmaking cost. When the pulverized coal injection is 200kg/t iron, the cost per ton of iron can be reduced by 80-120 yuan.

2. Energy conservation and emission reduction: The combustion of pulverized coal is more complete than that of coke, reducing CO2 emissions by 8%-12% per ton of iron; at the same time, it reduces the energy consumption in the coke production process (coke production requires a large amount of coal and electricity).

3. Capacity increase: Oxygen enrichment can increase the blast furnace air velocity and blast energy, accelerating the heating, reduction, and melting of the materials, shortening the smelting cycle by 5-10% per ton of iron, and increasing the blast furnace utilization coefficient (capacity index) by 5%-8%.

Oxygen-enriched coal injection in blast furnaces is a highly integrated system engineering project. Its technical core lies in creating a high-temperature and oxygen-rich combustion environment for coal injection through "oxygen enrichment", and achieving a dynamic balance and coordinated optimization between the two through refined process control (blast temperature, oxygen volume, coal volume, burden distribution, etc.). It represents the mainstream path of modern high-ironmaking technology towards high efficiency, low carbon and economy, and is an important indicator to measure the ironmaking technology level of a steel enterprise.